Leister UNIROOF 700 Automatic Roof Welding Machine 120V 1800W 169.237

The all new UNIROOF 700 120V 1800W 169.237 automatic roof welding machine is the most advanced machine for welding roof membrane yet developed. It's 10% faster at welding than the previous top of the range UNIROOF AT and over 30% faster than the UNIROOF ST, all with lower temperatures, lower voltage and stronger welds.

Description

Leister UNIROOF 700 Automatic Roof Welding Machine 120V 1800W 169.237

The all new UNIROOF 700 automatic roof welding machine is the most advanced machine for welding roof membrane yet developed. It is 10% faster at welding than the previous top of the range UNIROOF AT and over 30% faster than the UNIROOF ST.

Not only can the UNIROOF 700 weld roof membrane at speeds of up to 3.3m/min, but this can be achieved at lower temperatures (only 580ºC compared to 620ºC) than those required by the AT model. This not only saves time but creates high quality welds at lower power levels, ideal for construction sites where under voltage can occur. This is only possible because of the newly designed electronics which give the UNIROOF 700 sophisticated power management capabilities.

Eco Mode is a new feature that comes in with the UNIROOF 700, and is able to save up to 30% on energy consumption.

The UNIROOF 700 also comes with the latest LQS quality management data reporting and monitoring system with GPS and WIFI to give fast and accurate weld data of all the welding parameters including weld length and accurate GPS data for start and stop positions.

The machine is designed to overcome many of the issues seen on construction sites ranging from under voltage to lack of knowledge of the welding settings for specific materials and uncertainty of the quality of the welds produced.

Acknowledging the fact that up to 40% of the quality outcome for a weld is down to operator knowledge of the material and welding conditions (temperature, speed, air flow etc), Leister has introduced a new smart welding assistant. By automating the settings for specific materials by scanning a product QR code via the mobile app (Leister has worked with material manufacturers to create QR code labels for products with specific machine 'recipe' settings for each product) and monitoring the conditions against these parameters, the quality of roof membrane welding is dramatically improved.

Not only does the machine monitor and measure the roof membrane welding variables to ensure that quality waterproof welded seams are being produced; any variables which go outside these parameters alert the operator and, if activated, can stop the machine to prevent poor quality welds being produced.

Leister also realises that 20% of the quality outcome for a weld is down to the machine. This predominantly comes down to voltage, temperature and nozzle technology. To minimise the affect of these Leisters latest automatic roof welding machine includes closed loop technology allowing constant monitoring and adjustment of output to achieve a constant temperature and sophisticated power management electronics to elegantly handle supply under voltage.

Undervoltage can dramatically affect the quality of any welds. For example on a 120V machine, like the UNIROOF ST 120V, with the temperature set at 620ºC and airflow at maximum, under voltage at 100V can reduce the effective temperature of the weld from 620ºC to 475ºC. With the UNIROOF 700, this level if under voltage would result in a weld temperature of 610ºC.

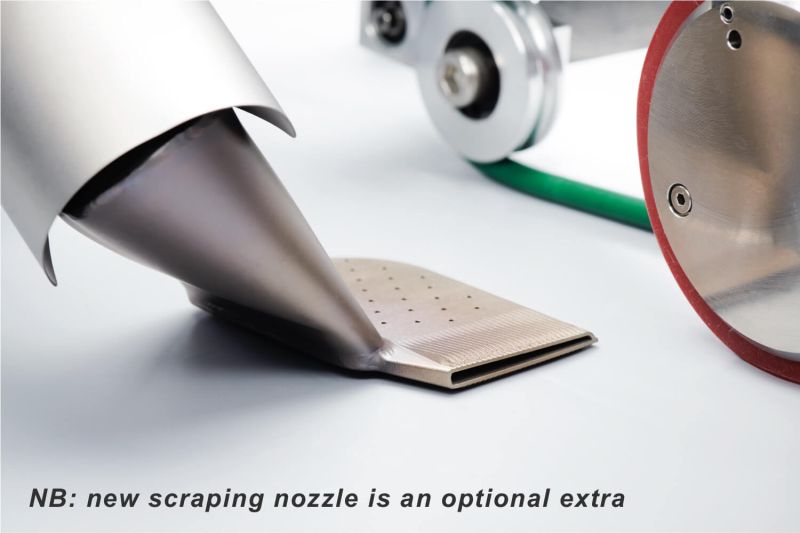

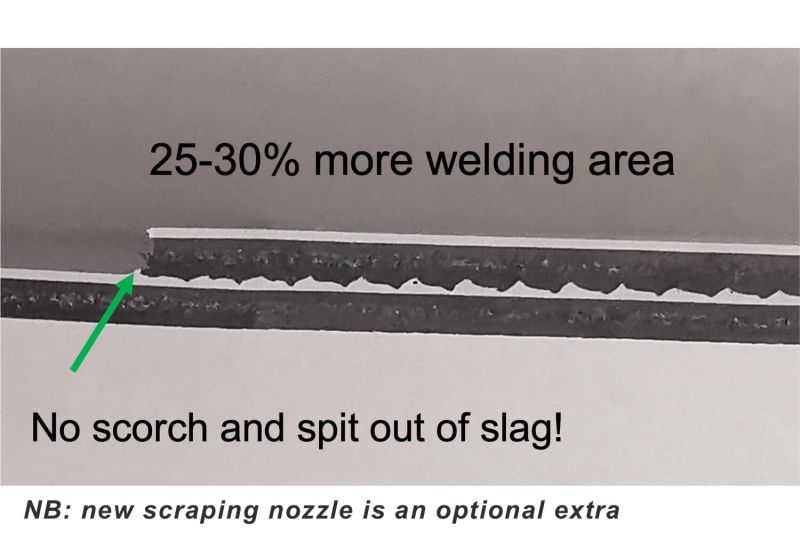

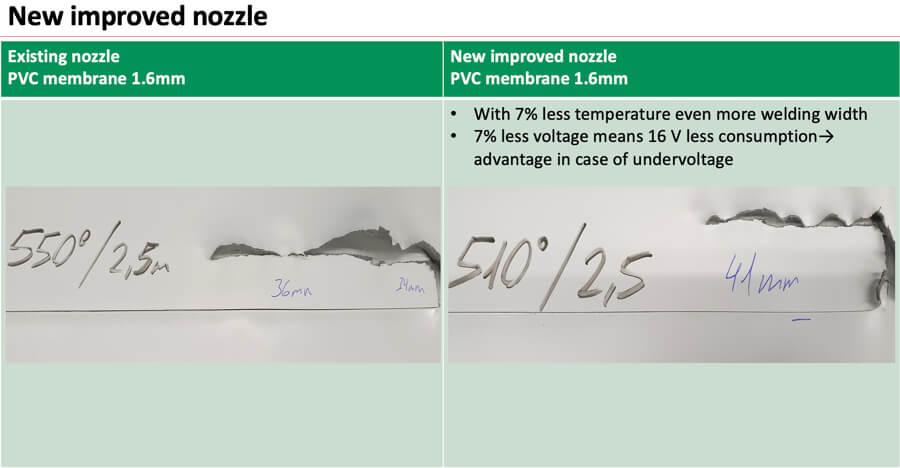

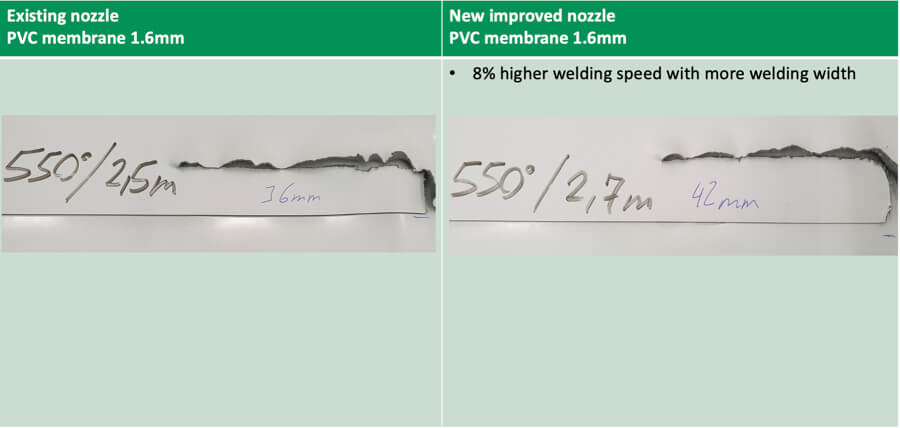

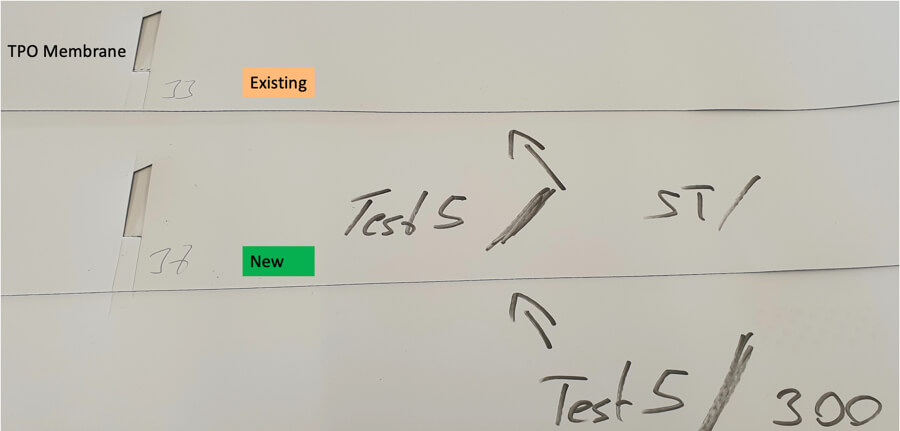

To improve the quality of the welds even further, Leister has developed a brand new patented nozzle design, the Scraping Nozzle, which will launch with the UNIROOF 700 and UNIROOF 300 and be available to purchase separately.

The new scraping nozzle (optional extra - see 170.119 under accessories & spares further down) creates a 25-30% larger surface area within the weld, a 12-16% wider weld width and produces a much stronger and more robust membrane weld with higher tear resistance and with minimal scorch and spit out of slag on PVC. Not only does the new scraping nozzle improve the physical weld quality it also allows for faster roof membrane welding speeds, lower temperatures and at a lower voltage than previously possible. The new design also virtually eliminates the need for solvents to clean the nozzle, better for productivity and for the environment.

NB: New scraping nozzle is an optional extra see 170.119

Scope of delivery:-

- UNIROOF 700 120V 1800W 169.237

- Standard Nozzle

- Carry Case

- User Manual

Specification

Leister UNIROOF 700 Automatic Roof Welding Machine 120V 1800W 169.237

Technical Specs:-

- Temperature Range: 100 - 620ºC

- Drive Speed: 1-10 m/min

- Airflow range l/min (cfm) @ 20ºC: 225 (45-100%)

- Display communication module: With traffic back light

- Brush less motors: Blower and drive

- Voltage display: Y

- Close loop: Y

- Monitor welding assistent with traffic light: Y

- LQS automatic data report GPS supported: Y (myLeisterApp)

- Powermanagement in case of undervoltage: Y

- Welding recipes: Y (myLeisterApp)

- Firmware update: Y (WiFi)

- WLAN connectivity: Y (WiFi)

- Eco Mode: Y (Save 30% energy consumption)

- Size L x W x H [mm]: 475 x 244 x 260

- Weight: 17Kg

Scope of delivery:-

- UNIROOF 700 120V 1800W 169.237

- Standard Nozzle

- Carry Case

- User Manual

Delivery

Standard Next Working Day Delivery

£4.50 +VAT for items up to and including £100 (ex VAT)

£7.50 +VAT for items over £100 (ex VAT)

Next working day applies to orders placed online before 3pm.

LEISTER Machines and Extruders

In order to tailor the correct machine to the correct job, for all LEISTER machines and extruders, we would recommend contacting our experts either online or via +44 (0)1707 331111 to discuss your needs and to place your order. For information these items are generally available as a next day delivery, if ordered before 3pm, with delivery charged at £11.95 +VAT

Delivery Exceptions and Exclusions

Unfortunately there are a few areas where next working day delivery isn't possible because of their remote location. However we always try to delivery to these areas within 2 working days. In certain circumstances items can sometimes take more than 7 days due to limited courier availability and weather conditions in these areas.

The restricted postcodes are as follows:

ZE, HS, KW, IV, AB, PH, DD, PA, BT, IM, GY, JE, PO (Isle of Wight).

Where restricted postcodes are on the Mainland delivery will be:

£4.50 +VAT for items up to and including £100 (ex VAT)

£7.50 +VAT for items over £100 (ex VAT)

A minimum of two working days applies to orders with Mainland restricted postcodes placed online before 3pm.

For restricted postcodes that are not on the Mainland delivery will be:

£14.50 +VAT for all items

For these items a minimum of two working days applies to orders placed online before 3pm.